Multi-Functional Coating and Scale-up

Hu Lab Research Direction

Key Takeaway

Vision Statement

Our Work

ALD coatings with atomic-scale precision are used to control interfacial phenomena, charge transport, and porous structures.

By augmenting light-driven synthesis, we address ALD’s scale-up challenges across energy, microelectronic, and environmental applications.

Impact

Utilizing our multi-functional coating design framework, we have achieved highly efficient photoelectrochemical energy conversion.

We significantly extended the lifespan of photoelectrochemical devices used in solar fuel production.

Research Background

Our Research Question

ALD (Atomic Layer Deposition) has emerged as a revolutionary technique in the world of thin-film coatings, offering unprecedented control and precision.

Unlike conventional coating methods, ALD delivers atomic-level thickness control, exceptional uniformity, and the ability to conform to the most complex geometries. Its dense, pinhole-free films, low-temperature deposition capabilities, and scalable nature make it an ideal choice for advanced applications in electronics, optics, and protective coatings.

Traditionally, ALD has found widespread use in industries such as semiconductor manufacturing, microelectronics, and optical coatings. The Hu lab continually discovers novel ALD materials for stable energy conversion.

Our Research Direction

To expand coatings for stable photoelectrochemistry, our lab leverages new ALD synthetic techniques with atomic precision to discover ternary coatings with tunable hole-transfer bands to stabilize a host of 1.1-2.3 eV bandgap semiconductors.

Our research focuses on advancing ALD techniques to engineer precise nanoscale coatings that optimize material performance for various energy and electronic applications.

By moving beyond conventional deposition methods, we leverage a fundamental understanding of interfacial chemistry and charge transport to design scalable and tunable thin-film systems with unprecedented control over composition, structure, and functionality.

To achieve this goal, we have been working on the following directions:

- Surface passivation and oxygen-free chemistry

- Tunable charge transport levels and band edge positions

- Transport selective porous ALD

- Light-driven scalable ALD

Our Research

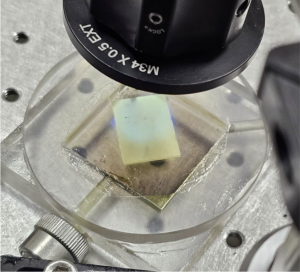

Low-Temperature Coating Technology: ALD

Our contributions redefine the boundaries of ALD innovation. From enhancing the performance of energy storage systems to providing durable corrosion protection and improving display technologies, ALD plays a pivotal role in delivering ultra-thin, high-performance, and conformal coatings that enhance both functionality and longevity.

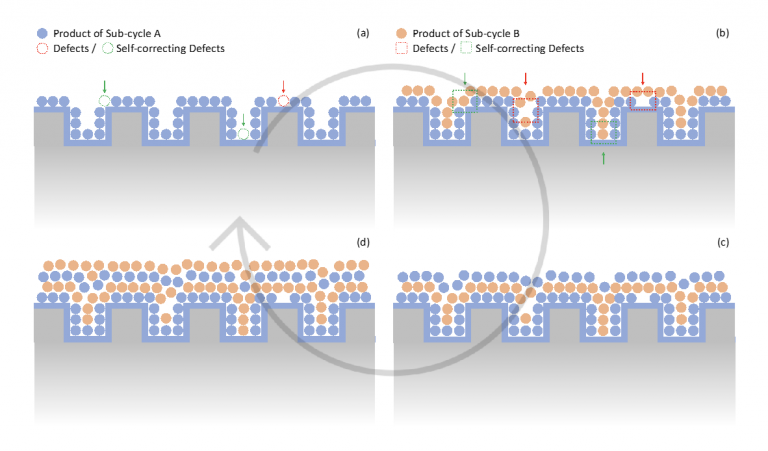

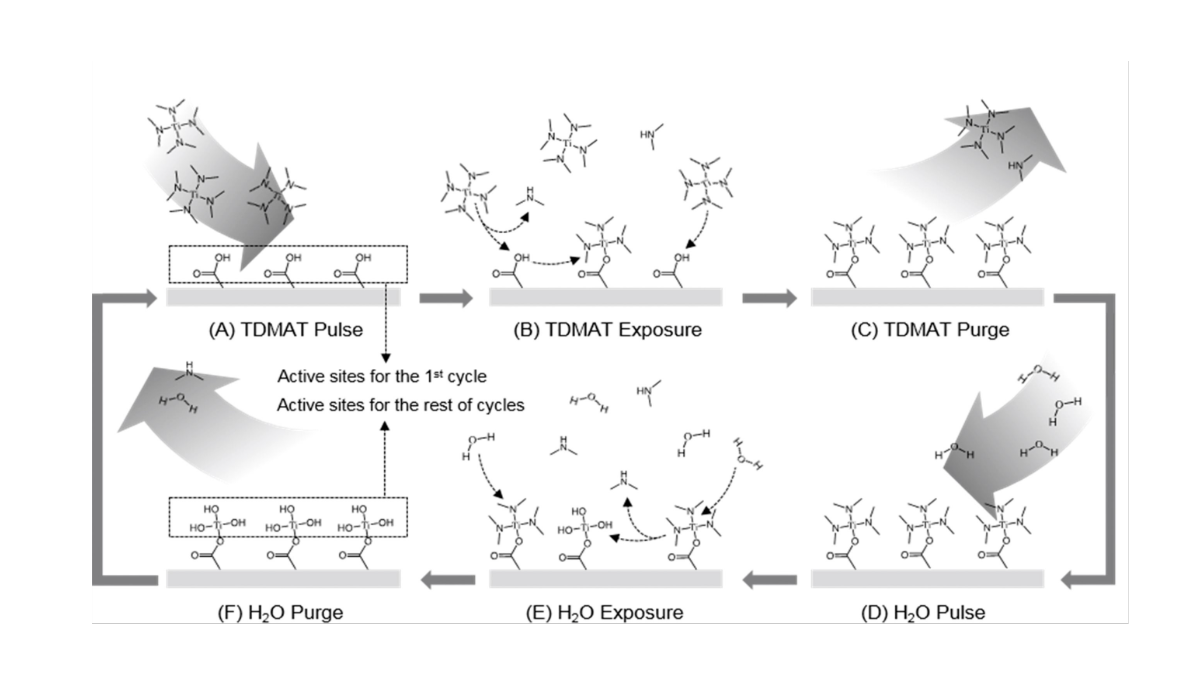

The schematic illustrates ALD, a precise, layer-by-layer coating process. It works by alternately exposing a surface to two different precursors. First, Precursor A reacts with the surface, forming a thin, controlled layer. Then, Precursor B reacts with this layer, completing the chemical reaction. This cycle repeats, gradually building a uniform and conformal film. The self-limiting nature of ALD prevents overgrowth, ensuring precise thickness control and defect correction, even on complex surfaces. This makes ALD a powerful technique for applications in semiconductors, energy devices, and advanced coatings.

Surface Passivation and Oxygen-free Chemistry

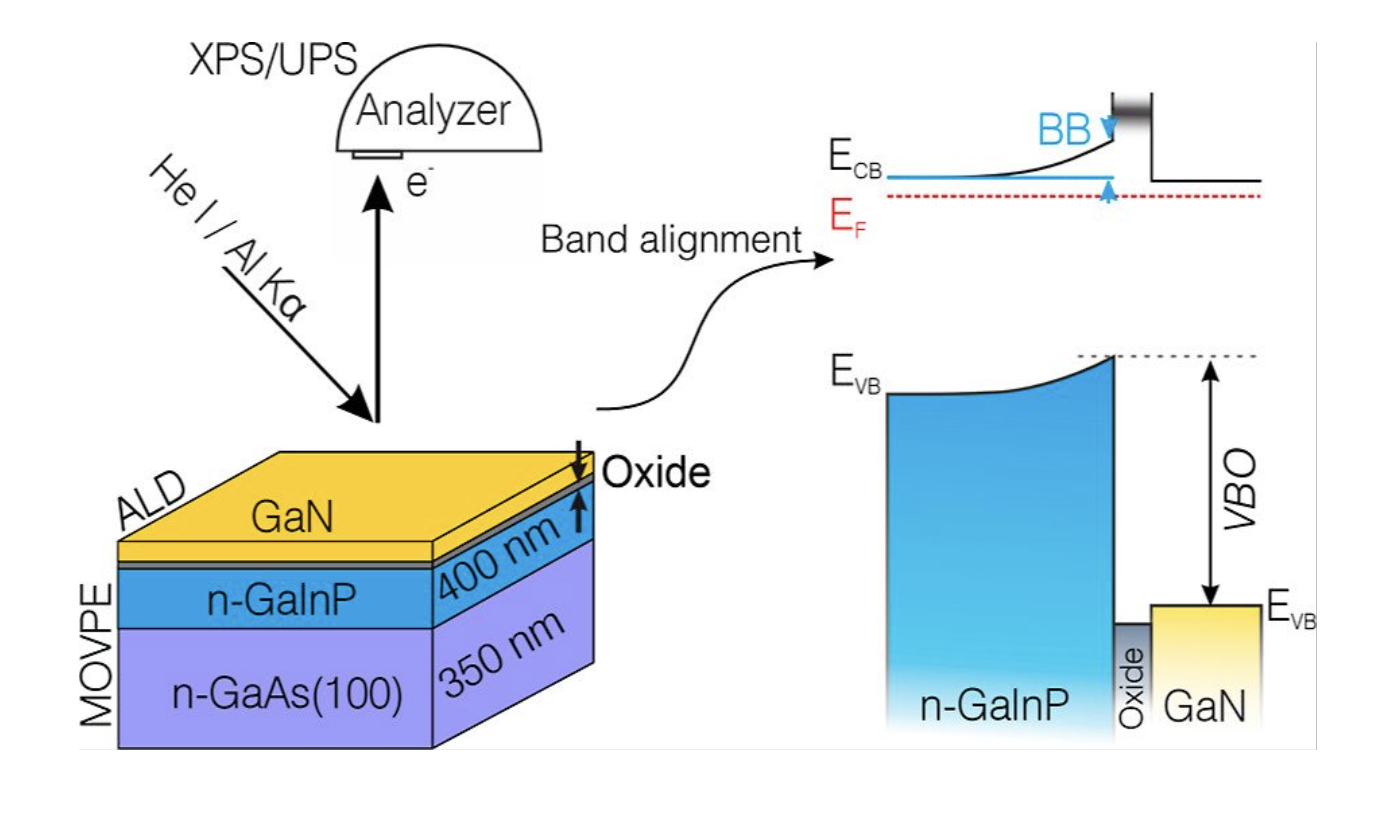

We utilize ALD-grown oxygen-free GaN for surface passivation, effectively preventing oxidation, reducing surface defects, and enabling selective charge transport at GaInP interfaces, significantly enhancing the stability and efficiency of photoelectrochemical cells.

Tunable Charge Transport Levels and Band Edge Positions

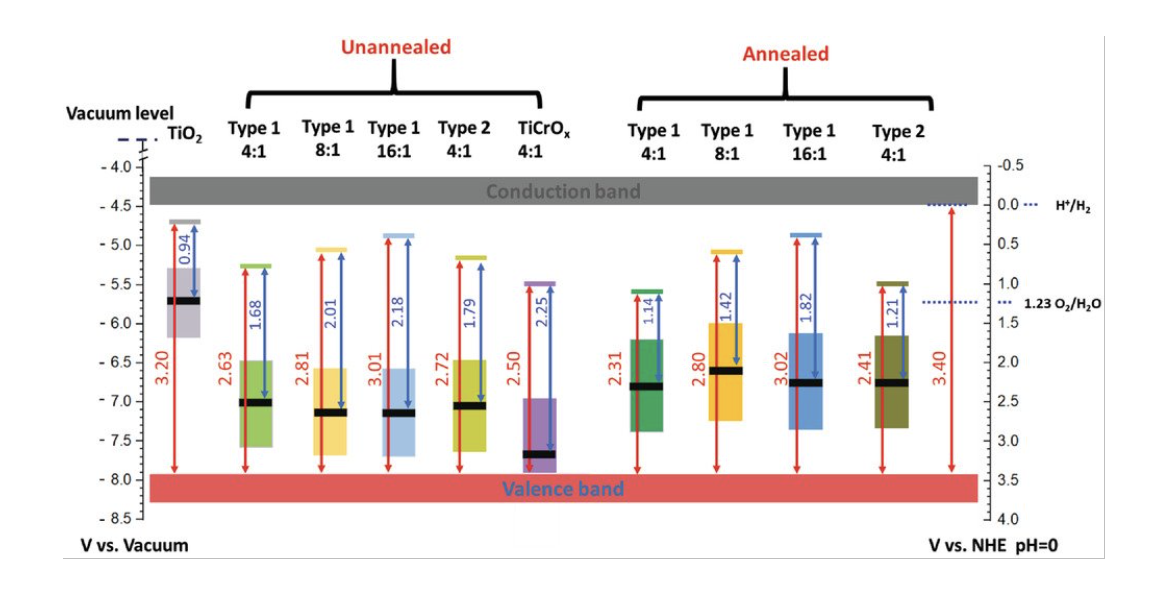

By alloying TiO₂ with transition metals via ALD, we precisely tune charge transport levels and band edge positions, optimizing energetic alignment with GaP photoabsorbers to enhance charge separation and transport in photoelectrochemical cells.

X. Shen, M. Yang, C. He, T. Zhao, D. Solanki, R. Yanagi, B. Gibbs, G. Krishnan, S. Hu, “Multicolor Bipolar Modulation of Titanium–Chromium Oxide Electrochromic Coatings” ACS Applied Electronic Materials, 5, 3, 1812-1823 (2023).

Transport Selective Porous ALD

By utilizing atomic layer deposition (ALD) to fabricate transport-selective porous membranes, we achieve precise control over pore size and surface charge, enabling selective ion transport and enhanced separation efficiency in environmental applications.

Zhou, R. Shevate, D. Huang, T. Cao, X. Shen, S. Hu, A. U. Mane, J. W. Elam, J.H Kim, M. Elimelech, “Ceramic Thin-Film Composite Membranes with Tunable Subnanometer Pores for Molecular Sieving”, Nature Communications, 14, 7255 (2023).

Zhou, Y.-Y. Zhao, S.-R. Kim, M. Elimelech, S. Hu, J. Kim, “Controlled TiO2 Growth on Reverse Osmosis and Nanofiltration Membranes by Atomic Layer Deposition: Mechanisms and Potential Applications”, Environmental Science & Technology, 52(24), 14311–14320 (2018).

Light-driven Room-Temperature CVD

By employing low-temperature, light-driven atomic layer deposition (ALD), we achieve scalable fabrication of high-quality thin films using cost-effective materials, enhancing the efficiency and affordability of large-area device manufacturing.

Hu, S. Light-Driven Coating Deposition Methods And Uses Thereof. U.S. Provisional Patent No. 63/648,374.

Conclusion

By developing ultra-thin TiO₂ coatings, we have significantly extended the lifespan of photoelectrochemical devices used in solar fuel production.

Additionally, we have introduced a scalable ALD-based approach for synthesizing high-quality single-layer 2D van der Waals materials, which not only improve material stability but also offer new prospects for advanced material synthesis.

These breakthroughs underscore the potential of precision-engineered ALD coatings in driving sustainable energy solutions and advanced material applications.

Acknowledgements & References

Papers:

S. Shekarabi, W. Zhang, Wolfram Jaegermann, T. Hannappel,* S. Hu,* “Photoemission study and band alignment at GaN passivation layers and GaInP(100) heterointerfaces”, ACS Applied Materials & Interfaces, 17 (4), 7087-7097 (2025). (*co-corresponding authors)

X. Shen, M. Yang, C. He, T. Zhao, D. Solanki, R. Yanagi, B. Gibbs, G. Krishnan, S. Hu, “Multicolor Bipolar Modulation of Titanium–Chromium Oxide Electrochromic Coatings” ACS Applied Electronic Materials, 5, 3, 1812-1823 (2023).

Zhou, R. Shevate, D. Huang, T. Cao, X. Shen, S. Hu, A. U. Mane, J. W. Elam, J.H Kim, M. Elimelech, “Ceramic Thin-Film Composite Membranes with Tunable Subnanometer Pores for Molecular Sieving”, Nature Communications, 14, 7255 (2023).

Zhou, Y.-Y. Zhao, S.-R. Kim, M. Elimelech, S. Hu, J. Kim, “Controlled TiO2 Growth on Reverse Osmosis and Nanofiltration Membranes by Atomic Layer Deposition: Mechanisms and Potential Applications”, Environmental Science & Technology, 52(24), 14311–14320 (2018).

Funding: